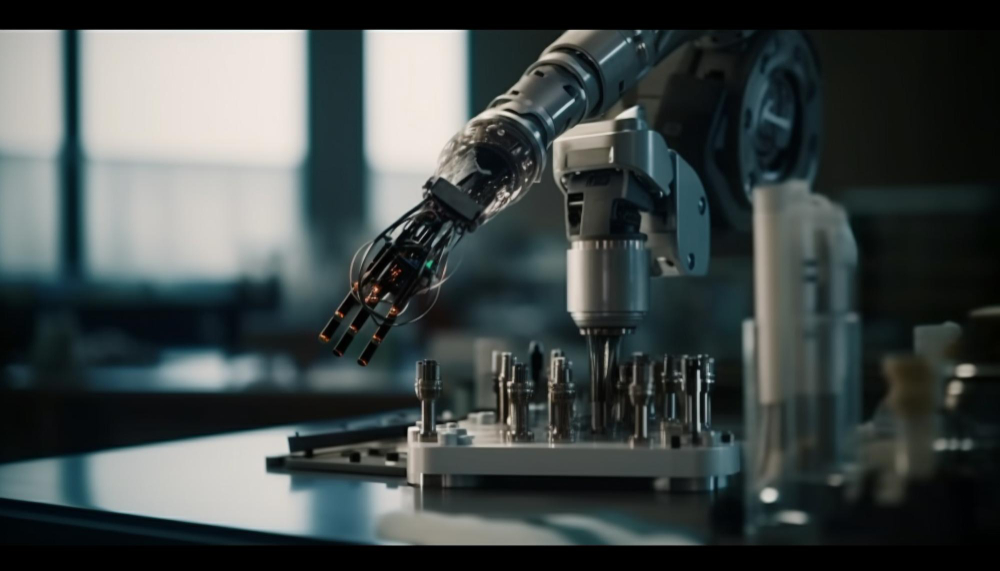

Unlocking the Power of Additive Manufacturing: Revolutionizing Industries

Additive manufacturing, also known as 3D printing, has emerged as a transformative technology across various industries. From aerospace to healthcare, its potential knows no bounds. Let’s delve into the remarkable capabilities of additive manufacturing and its impact on modern production processes.

A Game-Changer in Aerospace Engineering

In the aerospace sector, where precision and lightweight materials are paramount, additive manufacturing has revolutionized the way components are designed and produced. By employing advanced techniques such as selective laser sintering (SLS) and fused deposition modeling (FDM), aerospace engineers can create intricate parts with unparalleled accuracy and strength-to-weight ratios.

Elevating Healthcare with Custom Solutions

In healthcare, additive manufacturing has opened new frontiers in personalized medicine and prosthetics. With the ability to fabricate patient-specific implants and surgical guides, medical professionals can enhance treatment outcomes and reduce operating times. Furthermore, 3D-printed prosthetic limbs offer a comfortable and cost-effective alternative to traditional prosthetics, empowering individuals with mobility challenges.

Driving Innovation in Automotive Manufacturing

The automotive industry is no stranger to the benefits of additive manufacturing. By adopting 3D printing technologies, car manufacturers can streamline prototyping processes, accelerate product development cycles, and even produce end-use parts directly on the assembly line. This agility not only reduces time-to-market but also enables customization options for discerning consumers.

Enhancing Supply Chain Resilience

One of the most significant advantages of additive manufacturing is its potential to decentralize production and mitigate supply chain disruptions. By leveraging distributed manufacturing networks, companies can localize production, reduce shipping costs, and respond swiftly to changes in demand. This resilience is particularly crucial in volatile markets or during global crises.

Empowering Sustainable Practices

Beyond efficiency gains, additive manufacturing contributes to sustainability efforts by minimizing material waste and energy consumption. Traditional subtractive manufacturing methods often result in excess material scrap, whereas 3D printing builds objects layer by layer, optimizing material usage. Additionally, the ability to manufacture on-demand reduces inventory stockpiles and excess production, further lowering environmental impact.

Looking Ahead: The Future of Additive Manufacturing

As technology continues to advance, the potential of additive manufacturing will only expand. From bio-printing human organs to constructing habitats on distant planets, the possibilities are limitless. By embracing innovation and collaboration, industries can harness the full power of additive manufacturing to shape a brighter, more efficient future.

In Conclusion

Additive manufacturing has transcended its origins as a prototyping tool to become a cornerstone of modern manufacturing. With its ability to drive innovation, enhance customization, and bolster resilience, 3D printing is reshaping industries and unlocking new possibilities. As we look to the future, embracing additive manufacturing will be key to staying competitive in an ever-evolving global landscape.